Environmental Services:

Interceptor Maintenance

A Company representative will ensure that your requirements are fully understood and that all documentation, including Method Statements, Risk Assessments and other documents required by Health, Safety and Environmental legislation, are prepared in advance. Our fully trained personnel will be briefed on site specifics to enable us to provide its services with minimal disruption on your premises.

We are equipped with all the essential apparatus to complete all types of maintenance and clearance works including; hot and cold cutting equipment, high pressure jetters, breathing apparatus, confined space entry safety equipment, vacuum loading and DISAB tankers, which can be utilised by our fully trained operatives to provide you with an efficient and professional service.

We can also provide tank or plant decommissioning or even manage the entire site clearance should you wish. Ancorra would segregate materials on site, diverting all recyclable materials for recovery at a significant cost saving to the project and ensuring the remaining materials are safely treated and disposed of at a competitive rate.

On completion of works a report can be issued, detailing the tasks carried out and containing all the necessary documentation, providing you with a fully auditable summary of the project.

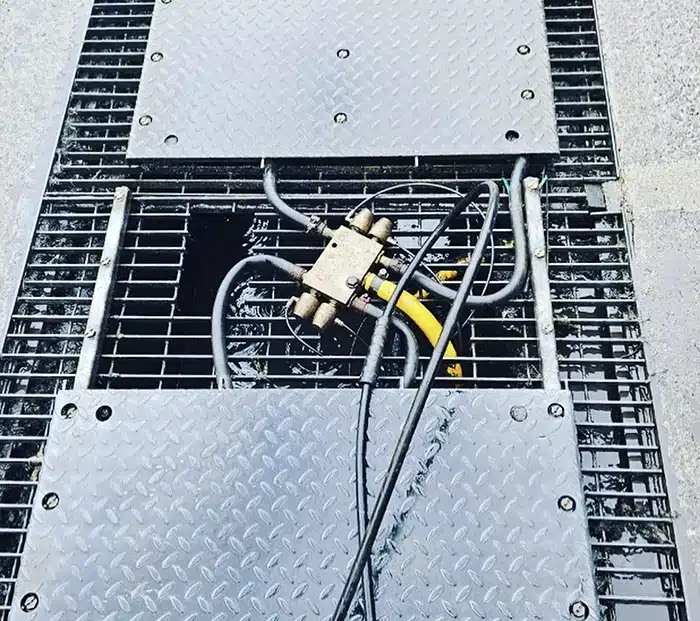

What are interceptors?

Interceptors separate the oil and grease from the wastewater, stopping these contaminants from entering the sewer system and becoming an environmental hazard. In winter, due to the danger of freezing, these critical components are more vulnerable to ice buildup and blockages.

When should interceptors be inspected?

Intuitively, your interceptors’ regular inspections and cleaning should be scheduled all year round. However, it is particularly important to not miss them during the winter months. When temperatures drop, oil and grease solidify, which can cause issues when the interceptor tries to separate them from the wastewater. What’s more, below-zero temperatures can lead to ice buildup inside the interceptor, blocking it.

What to consider before the Winter season?

To make sure your interceptors are working as they should be, you have to stop them from freezing and getting blocked. Being proactive, you should schedule a thorough inspection of your interceptors before the winter months have arrived – ensuring they are free of debris and sediment buildups.

Any repairs that need to be done should be completed before the winter sets in, to optimally reduce the risk of an environmental hazard when the temperatures drop. You can contact us for further details and costs – we are always happy to help!

In case of an emergency spill?

As they say, better safe than sorry! Things happen, and sometimes, despite your best efforts, spills happen. To be on the safe plan, you can work with our spill response team to develop a comprehensive emergency response plan for your separators in case of any blockages, freezing or interceptor failure. This includes protocols for addressing emergencies, our emergency lines and response times and a schedule for regular maintenance and inspections.

Our fully trained personnel will be briefed on site specifics to enable us to provide the services with minimal disruption on your premises.

In order to be effective interceptors require regular maintenance otherwise they will no longer contain oil and/or fuel from being released into the drain and they may become blocked from a build up of sludge. The Environment Agency advises, in Pollution Prevention Guide 3, that interceptors be inspected regularly and emptied as soon as a significant quantity of oil and/or silt has built up. We can empty and clean all types of interceptors and separators and are happy to provide a free site survey to assess your requirements and answer any queries. Our team will work with you to minimise any disruption to your business by efficiently emptying, re-filling and putting the interceptor back into service as quickly as possible.

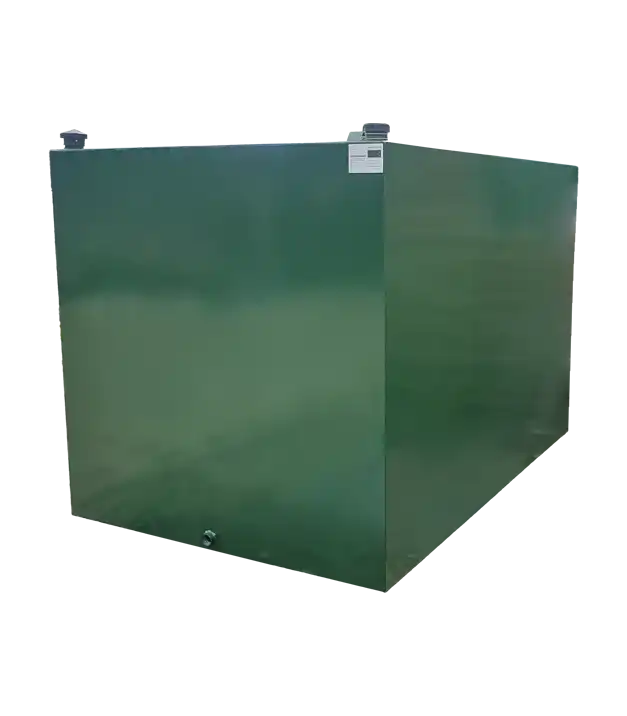

Benefits of Oil Tanks Plus

Made in the UK

Friendly experts

We recycle your old tank

Up to 12 year warranty

Nationwide coverage

Total one-stop shop for all your oil tank needs

Our friendly team of experts are here to give you the guidance you need to choose the right oil tank solution. We offer a free site survey before any installation and we can replace any old oil tank along with recycling it. Once installed, we offer maintenance and servicing across the UK.